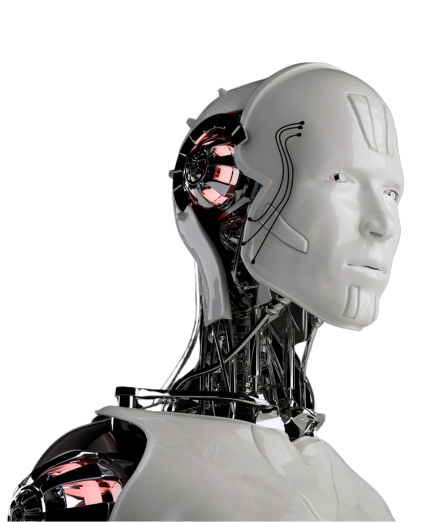

Robot welding is an advanced method of joining sheet metal parts using automated precision. At the heart of this process is a sophisticated robotic welding machine, meticulously programmed to navigate along the designated path of the components awaiting fusion. With unparalleled accuracy and consistency, these robotic welders execute welds with meticulous attention to detail, ensuring seamless connections between the metal parts.

Equipped with a diverse array of sensors and actuators, these robots possess the agility to adapt to various contours and shapes of the components, effortlessly maneuvering along the intricate paths dictated by the welding requirements. Through a combination of computer algorithms and real-time feedback mechanisms, they optimize their movements to achieve optimal weld quality, minimizing defects and enhancing overall productivity.

In essence, robot welding represents the pinnacle of modern manufacturing, where the synergy between cutting-edge technology and precise engineering converges to deliver superior results in terms of speed, accuracy, and reliability. By harnessing the power of automation, industries can significantly elevate their welding processes, unlocking new levels of efficiency and precision while ensuring consistent and high-quality welds across production lines.